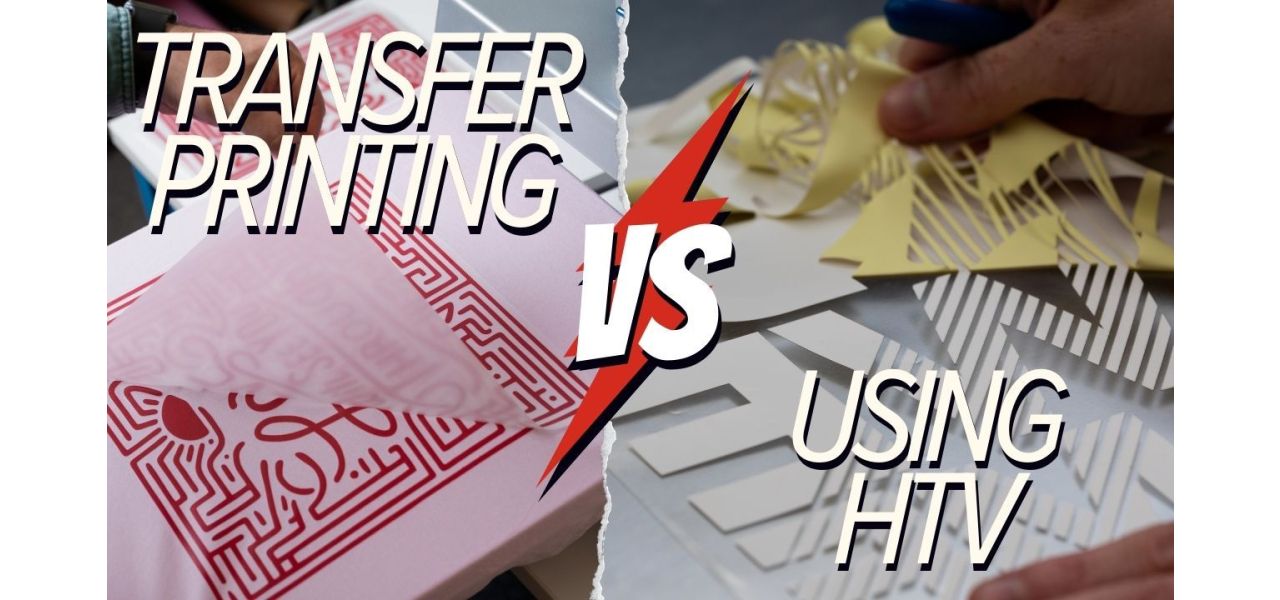

Transfer prints vs. HTV - the advantages and disadvantages in a nutshell!

Transfer printing is a relatively new process for decorating textiles.

It offers a time-saving alternative to the tried and tested work with heat transfer vinyls.

At the same time, working with transfer prints also eliminates some of the options you have with foils.

Which material is better for you?

Take a look at the advantages and disadvantages of both.

Contents

- Transfer printing

1.1 Advantages of transfers

1.2 Disadvantages of transfers - Heat Transfer Vinyl

2.1 Advantages of HTV

2.2 Disadvantages of HTV - Conclusion

1. Transfer Printing

With transfer printing, you give your graphics to a transfer manufacturer.

They then turn them into prints that you can apply directly to a textile using your heat press.

1.1 Advantages of transfers

Colors and photos

With transfers (for example DTF transfers and digitally printed) it is possible to turn photos into textile decorations.

For example, you can take a beautiful portrait and transfer it to a textile with realistic colors and a high level of detail.

It is also possible to let colors flow into each other.

Please note: the quality of your transfer makes a big difference here! Many DTF providers, for example, are not able to display an intensive play of colors in their prints.

The best thing to do here is to test which manufacturer can adequately reproduce your motifs.

No additional equipment

Another advantage of transfer printing is that you don't need any additional equipment.

There are no additional initial costs and no space that you need to keep free for a machine.

Order on demand

With transfers, you have no storage costs.

This is because you have the option of ordering on demand - i.e. only ordering when you need them for an order.

It's worth choosing a manufacturer that can produce your transfers as quickly as possible and is based in your country.

STAHLS', for example, produces in Dillingen (Saar), Germany. We produce your DTF transfers in a maximum of 48 hours and can also offer a 24-hour production time for all transfer types on request.

Cover all orders with different transfers

Transfers give you the opportunity to process different orders right from the start.

There are screen printed transfers - perfect for large orders with few colors, digitally printed transfers - for large orders with many colors, DTF transfers for all orders with small quantities.

And for dyed polyester fabrics, you can also order the screen printed and digitally printed transfers as a sublistop version.

Thanks to the different transfer types, you are immediately able to process most orders.

You don't need a large production or a lot of experience as a textile printer, but can start immediately.

Perfect for getting started

This also makes working with transfers the ideal way to get started in textile printing.

Over time, your business will grow and your orders will get bigger - again, manufacturers with comprehensive, fast transfer production offer you everything you need to run a successful textile printing business.

1.2 Disadvantages of transfers

No special effects possible

One thing that transfer users have to do without are special effects.

Special surface structures, finishes or special light effects cannot be implemented in transfer printing.

These include, for example, reflective effects for work clothing or the popular glitter effects.

Planning effort

If you suddenly have a sensational idea for a motif in the evening, you can't print it immediately.

While plotter films allow you to decorate textiles at any time, with transfers you first have to order your materials. If you have ordered too few transfers for a customer order or mess up when decorating with them, you will also have to wait a few days for your repeat order - to avoid this, we always recommend ordering more transfers (and textiles) to have a small buffer.

Dependence on the transfer manufacturer

Even if you have your own print store and can work largely independently, you are still dependent on your manufacturer.

Make sure you research whether your manufacturer offers you fast delivery times, a high level of quality control and a good selection of different transfer types.

Heat Transfer Vinyl

HTVs are still a popular way of decorating textiles.

In the hobby sector, people like to use the various films, cutting machines and presses to express themselves creatively or to make gifts for their loved ones.

However, many companies also use plotter film to process their customer orders.

Advantages of HTV

Attract attention with special effects

Special effects are something that only HTVs can offer you.

There is now a huge selection available: From velvety-soft flock foil to glitter foil and foils that glow in the dark.

Especially if you print your own motifs on textiles as a brand, heat transfer vinyl can be your chance to stand out from the competition.

Special opportunities for fulfillment

Working with heat transfer vinyl can also be interesting if you process your customers' orders in fulfillment.

With certified Reflect film, for example, it is possible to print workwear for other companies.

Easy to store

Heat transfer vinyls are easy to store.

Either as a stack of blanks or in roll form. Having the film you use regularly ready at all times gives you security and allows you to work when you want to.

Disadvantages of HTVs

Weeding

Many companies have switched from plotter film to transfer printing because it saves them a huge amount of time.

Vinyl must first be cut and then weeded by hand. This is where the film residues are removed from the motifs - depending on the complexity, this can take a lot of time and cannot be automated.

However, there are also some tools that make the process of weeding much easier, or a weeding service to have your motifs sent to you already finished!

You can simply send us a message to info@stahls.de with your file as a vector graphic and we will create a customized offer for you!

Cutting plotter required

You need an additional machine to process HTVs: a cutting plotter.

These are available in different versions, which differ in terms of speed, materials they can cut and, of course, price.

In any case, you need to create the necessary space for your cutting plotter and be able to pay the initial investment before you can finish textiles with your vinyl.

Conclusion

Decide for yourself which type of printing suits you better - fast, effortless work with transfer prints or the limitless creativity of HTVs?

Or go a third way - combine the advantages of DTF transfers and foils!

In this video, we show you how this can work!