What is the best heat transfer vinyl for printing on polyester?

Polyester is a popular material in the textile industry, mainly due to its durability, durability and ease of care.

However, these properties also make polyester a challenge to print on with HTV.

To choose the best vinyl for printing on polyester, you need to consider various factors, including the specific properties of polyester and the special requirements of sublimation-dyed polyester textiles.

Properties of polyester fabrics

Polyester is a synthetic fabric that is known for its robustness and resistance to shrinkage and stretching. Polyester fabric is ideal for sports and leisure wear because it wicks away moisture and dries quickly.

When printing polyester with HTV, the heat sensitivity of the material is a critical point.

Polyester begins to melt or change its shape at temperatures above 160°C, which is why precise temperature control is necessary during the printing process.

Temperature requirements for printing

When decorating polyester textiles with vinyl, the printing temperature should be in the range of 130°C to 150°C.

Too high a temperature can damage the material, while too low a temperature may not activate the adhesive of the HTV properly.

In addition, the duration of the heat exposure is crucial; a pressing time of 10 to 15 seconds is usually sufficient to achieve an optimum result without overheating the material.

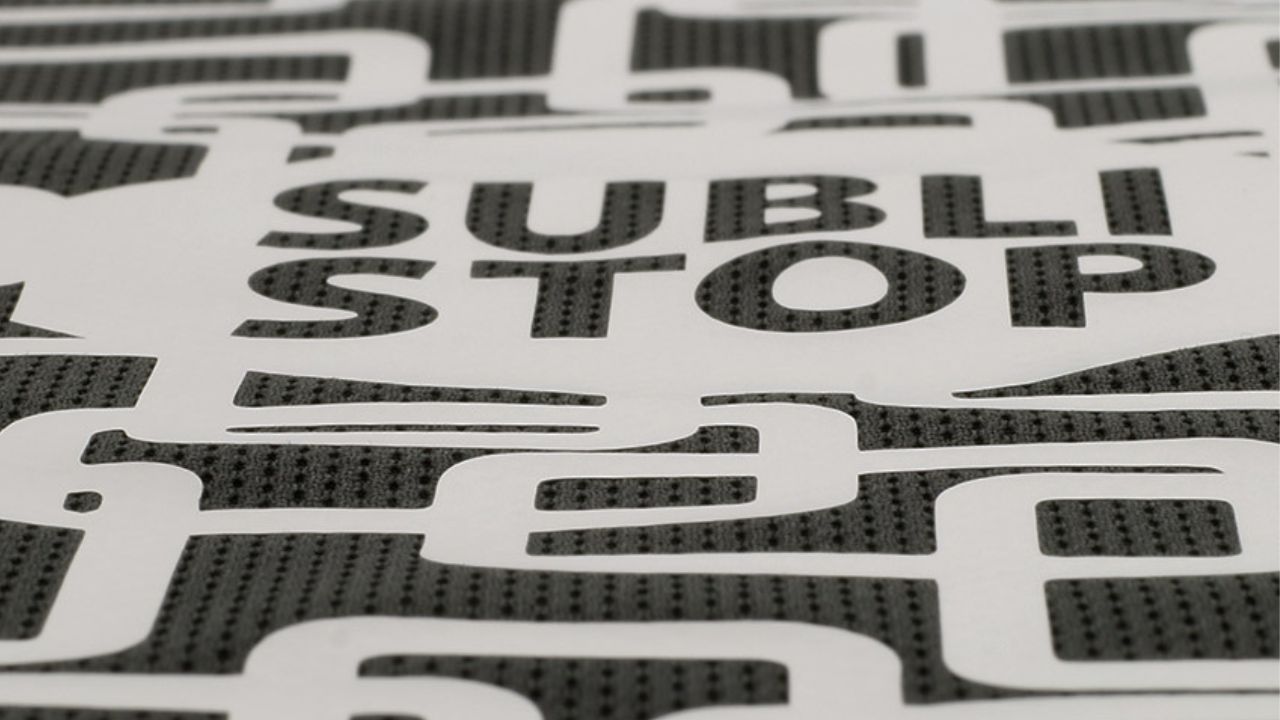

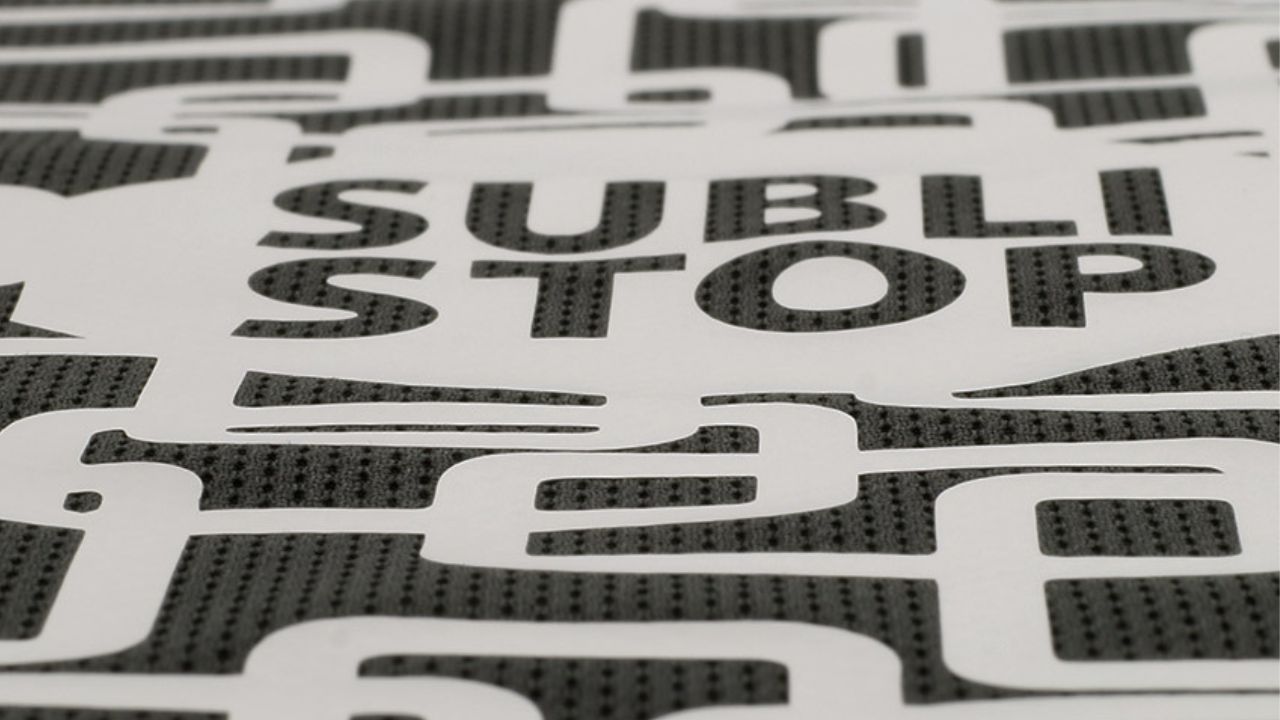

Sublimation-dyed polyester

Sublimation-dyed polyester is a particular challenge when printing with plotter film.

In sublimation printing, the color is burned into the material and can reactivate when heated. This can lead to color gradients or discoloration if no suitable vinyl is used.

To avoid this color migration, an HTV with a sublimation blocker should be used.

These special foils prevent the dyes in the polyester from sublimating again when heated and emerging through the printed motif.

CAD-CUT® Premium Plus Sublistop, for example, is a high-quality film with a sublimation stop layer.

Choosing the best heat transfer vinyl

When choosing the best material for polyester, you should consider the following properties:

- Low activation temperature: the film should be able to be activated at a relatively low temperature to minimize the risk of damaging the polyester fabric. Films that work at temperatures of 130°C to 150°C are ideal.

- Elasticity and durability: As polyester is often used for stretchy garments, the plotter film should be elastic and able to move with the material without tearing or coming loose.

- Sublimation blocker: For sublimation-dyed polyester, it is essential to choose a film with an integrated sublimation blocker. These prevent color changes and ensure a clean and clear print image.

- Good adhesion: The film should have strong adhesion to polyester in order to remain intact even after numerous wash cycles.

Conclusion

The optimum HTV for printing polyester textiles should have a low activation temperature, be elastic and durable and, especially in the case of sublimation-dyed polyester, have a sublimation blocker. These properties ensure that the printing process does not damage the material, the colors remain brilliant and the design remains intact even after repeated washing.

STAHLS' heat transfer vinyls offer you these essential quality features with a wide range of colors and special effects. Browse through our selection of plotter films now!